Project: Atwood Lake Cemetery Bay Connector Trail

Muskingum Watershed Conservancy District, 2050 Reiser Avenue SE, New Philadelphia, OH 44663

Architect: GAI Consultants Inc.

3720 Dressler Rd NW, Canton, OH 44718

General Contractor: Shrock Premier Custom Construction

234 West Main Street, Loudonville, OH 44842

Deep Foundation Contractor: Ecoseal Home Solutions

4535 Township Rd 367, Millersburg, OH 44654

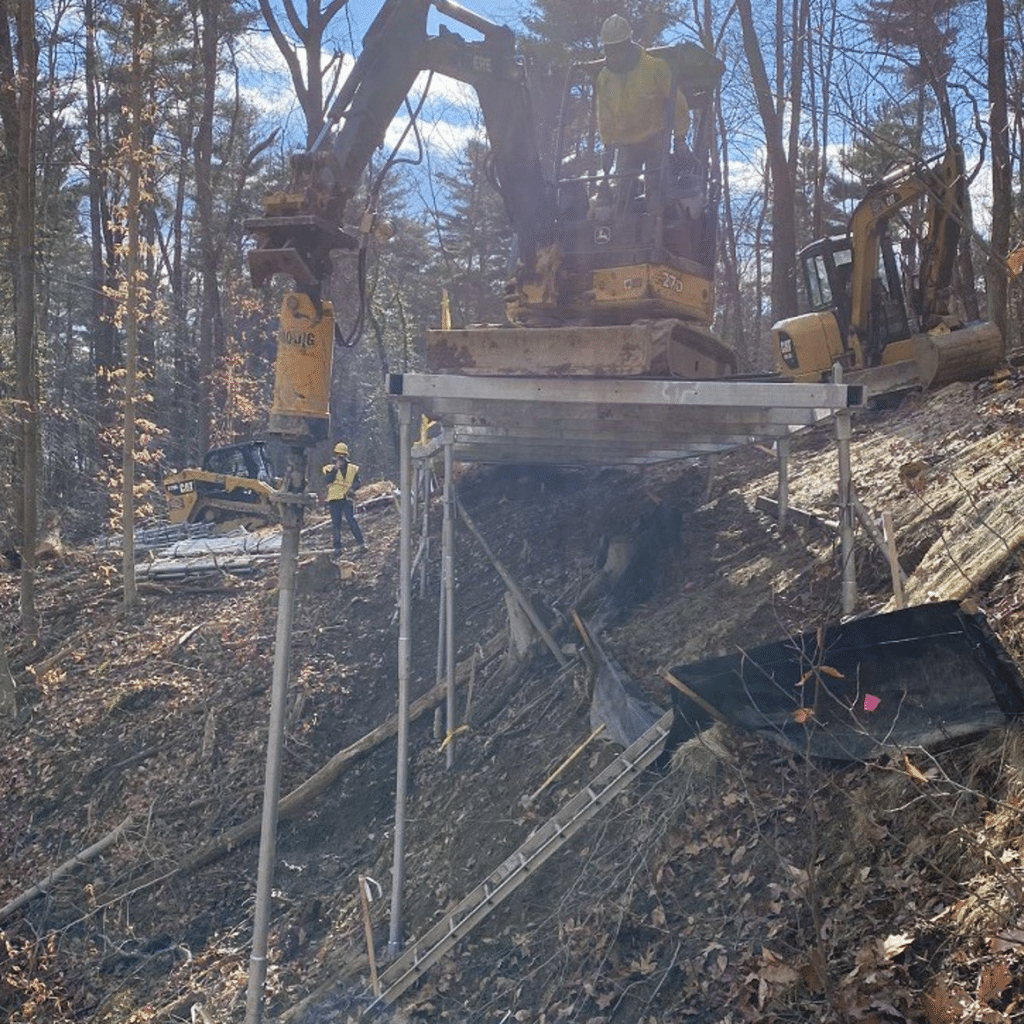

The Muskingum Watershed district was building a 250’ long boardwalk through an environmentally sensitive area. The boardwalk was designed to be supported by helical piles and the highest point of the boardwalk would be 13’ above grade.

The loads on the piles would have an ultimate load of 20 kips but it also had to be designed to support a 7500 lbs. machine to drive across the boardwalk. The frame of the boardwalk is steel framing provided by Wickcraft Boardwalks.

Performance Piers worked with Ecoseal Home Solutions to provide a design that would meet the loads required for the project. The pile chosen for the project would be a 2.87” OD pile with an ultimate load rating of 85.5 kips. Because the 2.87” pile would only support these loads with a total unbraced length of 11’ battered piles would be required to support the unbraced lengths.

A 2.37” OD battered pile with a lateral support bracket attached to the pile and bolted to the vertical pile approximately 2’ below the boardwalk. This would take care of the unbraced length and keep it less that 11’.

The boardwalk would also have to be built in stages because the machine would have to install the piles from the boardwalk due to not being allowed to take machinery into the Environmentally Sensitive areas.

Several piles would be installed and then the Wickcraft frame would be set in place. Then plywood was placed on the frame of the boardwalk and the machine was taken out onto the plywood to install the next set of piles. Then the process would be repeated.

The engineer on site that observed the installation mentioned we had the best connection of battered piles to vertical piles they had seen and would be recommending our design on future projects. 32 vertical piles and 18 battered piles were installed in 9 working days and the project was completed on time.