Helical Piers

Helical piers or piles, originally called “screw piles” have been used in applications since 1833, when they were first patented. A helical pile is simply a steel shaft with one or more helical plates welded to the shaft. The shaft of a helical pile can be either square bar (RCS) or steel pipe. Typical helical piles can have one helical plate on the lead shaft or as many as three. As extensions are added to the lead section and advanced into the soil, the extensions can have helical flights as well.

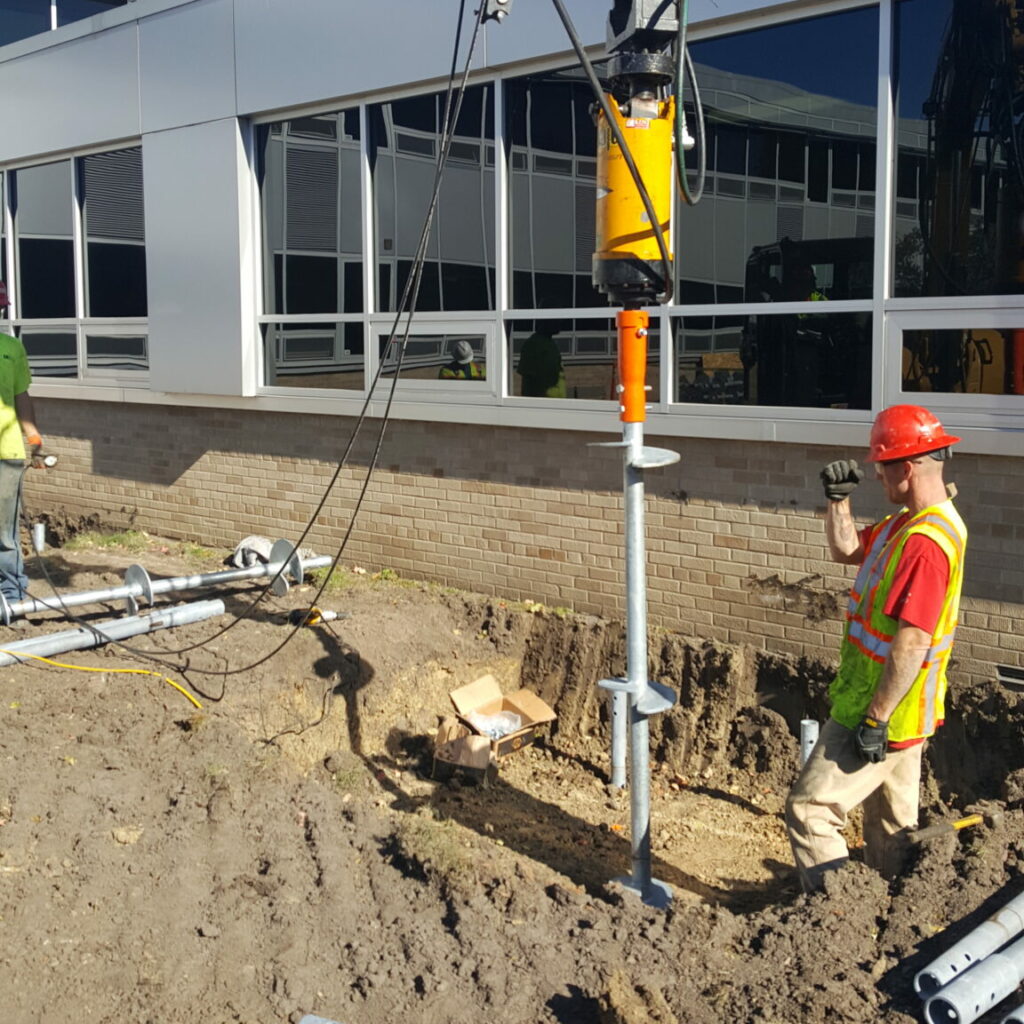

How Helical Piers Are Installed

Helical piles or piers are advanced into the soil using a drive motor attached to a skid steer, mini-excavator, or similar machines. As the pile is advanced into the soil, the resistance to screw the pile into the ground is monitored by torque. The amount of torque applied directly correlates to the pile’s load-bearing capacity.

How Helical Piers Work

A helical pile or helical pier has three components: The shaft, helical plates, and connection to the structure. The shaft provides four functions: To provide sufficient torque capacity during installation, to provide load transfer from the helices to the shaft, to provide a connection to the structure, and to transfer load from the pile to the structure.

The helical plates have three primary functions: To provide pulling power to advance the pile into the soil, to provide torque and bearing capacity, and to transfer the load into the soil to support the structure.

The connection to the structure: This can be done with a wide variety of components but the most common is a bracket embedded in concrete. This connection must be able to support the required load and transfer the load to the structure.

Why Helical Piles Are The Right Choice

Helical piles have a wide variety of applications for both compression and tension, and they can obtain load bearing capacities of over 500 kips.

Following are the advantages of helical piles:

- They can be installed in constricted areas to get a high-capacity pile.

- Small equipment can be used to install the piles.

- They can be installed in hazardous material, thus eliminating the costly expense of disposing contaminated spoils.

- They can be immediately loaded.

In addition, when designing a helical pile the following considerations must be taken into account:

- Buckling of the shaft.

- Lateral capacity, embedment length.

Contact MHS to assist you in designing the correct helical pile for your project.